Planetary Gear Motor Manufacturer in China

with 24 Years of Experience

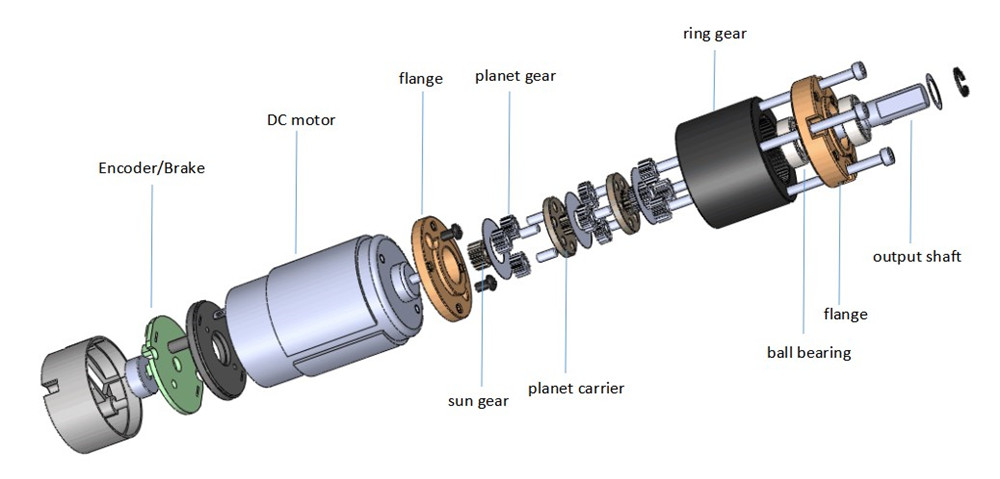

What is a planetary gear motor? A planetary gear motor is a combination of a planetary-type gearbox and a DC motor with the features of speed reduction, high transmission efficiency, smooth power output and high torque. Twirl offers an extensive selection of custom-designed gear motors to specifically match your project’s requirements.

Request a Quote Today

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Submit Request

DC Planetary Gear Motor Supplier

● TWIRL is a world leader in the design and manufacturing of customized gear motors. Our gear motors are renowned for their smooth, controlled power delivery and high torque.

● From configurable to fully customizable, Twirl offers Gearmotor solutions to meet specific OEM requirements.

● Since different cases normally hold different needs and demands, custom gearboxes are of great importance so that different needs can be satisfied individually.

● In-house manufacturing of own gearing tools as well as treatment and hardening processes, the production of precise gearing components, gearboxes and technical parts are core competencies of TWIRL.

● From configurable to fully customizable, Twirl offers Gearmotor solutions to meet specific OEM requirements.

● Since different cases normally hold different needs and demands, custom gearboxes are of great importance so that different needs can be satisfied individually.

● In-house manufacturing of own gearing tools as well as treatment and hardening processes, the production of precise gearing components, gearboxes and technical parts are core competencies of TWIRL.

Why Choose Us

Engineering Excellence

Twirl Motor has the engineering capability to meet your design requirements.

Flexible Manufacturing

Twirl's lean optimized manufacturing floor can accommodate both large and small orders.

Quality Reliability

Key Components are completely Home-Made. IATF16949 management system ensures product quality accuracy and productivity.

Competitive Cost Control System

Our perfect and stable supply chain system. Automated production and very low defect rates have reduced costs.

Effective Communication and Collaboration

The customer needs analysis team responds to customers quickly and professionally. Professional sales engineers provide one-stop customized services.

Request a Quote Today

Main Certificate

Buying FAQ

1

Can the motor run in CW (clockwise) and CCW (counter-clockwise)?

Yes, all of our Brushed DC and Gear Motor can be used in both CW and CCW.

Normally direction of Rotation is CCW when viewing from the output shaft end with positive

the voltage applied to the positive terminal.

2

If I don't know how much torque I need, how can I figure it out?

There is a simple way to figure it out. You just need to send us the rough torque range, and the dimension limitation, then we will offer a type for you and make a few samples to test. During the testing, we can offer a simple method to check it out.

3

How to reduce the motor noise?

This is a constantly and usually asked question. Twirl has 10+ years of experience with noise control experience, we have many ways to handle different noises, like different gear materials and production technics, grease and DC Motor control.

4

Can Twirl customize the motor?

yes, most of motors supplied to current customers are customized, like the customized voltage, speed, torque, current and noise; customized dimensions, like a shaft, motor body, extra cable&connector, worm, gear support, etc.

5

Can I get samples for testing before ordering?

When you need samples for testing, please contact us directly, will answer your inquiry no later than 24 hours.

6

What is the lead time for samples and bulks?

It depends. For samples, It is about 12 days.

For bulk production (5000pcs or below), About 30 days.

For bulk production (5000pcs above), About 50 days.

7

What is your MOQ?

It depends on motor types, Pls discuss with our sales on line.

8

What is your payment term?

T/T, L/C, Western union etc, We can further discuss.

9

What is your delivery term?

Ex Works, FOB Ningbo/Shanghai, FCA, CIF discharge port, CIP destination airport, DDU those are what we always do so far.

| Standard product of TWIRL planetary gear motor ASSEMBLY: | ||||||

| Model | Diameter | Voltage | Speed | MAX rated torque | Power | Encoder type |

| PG16050 series | 16mm | 3V~24V | 3~2000rpm | 4kg.cm | 0.3~1 Watt | |

| PG22180 series | 22mm | 3V~24V | 5~2000rpm | 4kg.cm | 1~4 Watt | ME-180(1ppr,3ppr) |

| PG25370 series | 25mm | 12~24V | 5~2000rpm | 10kg.cm | 0.3~2 Watt | |

| PG28395 series | 28mm | 12~24V | 1~1500rpm | 50kg.cm | 3~10 Watt | ME-28(3ppr, 7ppr) |

| PG32395 series | 32mm | 12~24V | 1~1700rpm | 50kg.cm | 3~10 Watt | ME-28(3ppr, 7ppr) |

| PG32555 series | 32mm | 12~24V | 1~1500rpm | 50kg.cm | 4~20 Watt | ME-37(3ppr, 7ppr) |

| PG32GR series | 32mm | 12~24V | 1~1500rpm | 50kg.cm | 1~8 Watt | ME-GR(3ppr, 7ppr) |

| PG36GR series | 36mm | 12~24V | 1~1500rpm | 100kg.cm | 1~8 Watt | ME-GR(3ppr, 7ppr) |

| PG36555 series | 36mm | 12~24V | 1~1500rpm | 100kg.cm | 4~20 Watt | ME-37(3ppr, 7ppr) |

| PG42775 series | 42mm | 12~24V | 1~1500rpm | 200kg.cm | 6~40 Watt | ME-775(3ppr, 7ppr) |

| PG45775 series | 45mm | 12~24V | 1~1500rpm | 200kg.cm | 6~40 Watt | ME-775(3ppr, 7ppr) |

| PG45ZY45 series | 45mm | 12~24V | 1~2000rpm | 200kg.cm | 10~40 Watt | |

| PG52ZY52 series | 52mm | 12~24V | 1~2000rpm | 300kg.cm | 30~60 Watt | |

| PG56ZY58 series | 56mm | 12~24V | 1~2000rpm | 400kg.cm | 30~80 Watt | ME-3237D(13ppr)/brake |

| solar tracker motor | 115mm | 12~24V | 2.5rpm | 2900kg.cm | 80 Watt | |

TWIRL Planetary Gear Motor Catalog

Choose Professional Planetary Gear Motor Manufacturers and Suppliers

As a leading manufacturer of planetary gear motors in China, we can help you provide more affordable planetary gear motors. Our reliable quality can help you expand your business.

Planetary Gear Motor

TWIRL MOTOR products consist of gearbox ,motor ,encoder and brake components.

- Outer Diameter: 16mm – 115mm

- Voltage: 3V,6V,12V,18V, 24VDC

- Output power: 1Watt ~80 Watt

- Rated torque: up to 290 Nm

- Rated speed: 1rpm ~ 2000rpm

Customized Options

Total DC motor solutions could be customized based on different appllication conditions.

- Professional DC gear motor customization at various RPM, torques, OD, voltages, flange, and IP ratings.

- Output shaft: extended, slotted, cross-drilled, D-cut, Keyway, round, Hexagon, Splined

- Lead wire: special lengths, heat shrink, connectors, cable harnesses.

- Bearing & lubricant for high temperature/humid operations

- Power-on or power-off type electromagnetic brake,encoder+brake Option

- Capacitor& resistor for EMC suppression.

Contact Now

Submit Request